In Dubai’s desert hinterland, a 200-sq-m smart home sprang up in 8 hours. 42 pre-equipped folding container modules arrived via flatbed trucks, with workers unlocking hinges via crane – reducing volume 60% vs standard units.

Folding Tech Breaks Logistics Barriers

Instant Deployment: German hinge systems auto-unfold in 90s, cutting labor 85%

Slim Transport: UK’s 1.2m ultra-thin modules triple shipping capacity

Eco-Integration: Singapore’s solar roofs activate upon unfolding

Disaster Response Reshapes Market

Turkey earthquake: 7,200 units/month, 12 units/hour installation

NHCR orders ↑150%, 65% adoption in African camps

California wildfires drive 300% US Southwest capacity expansion

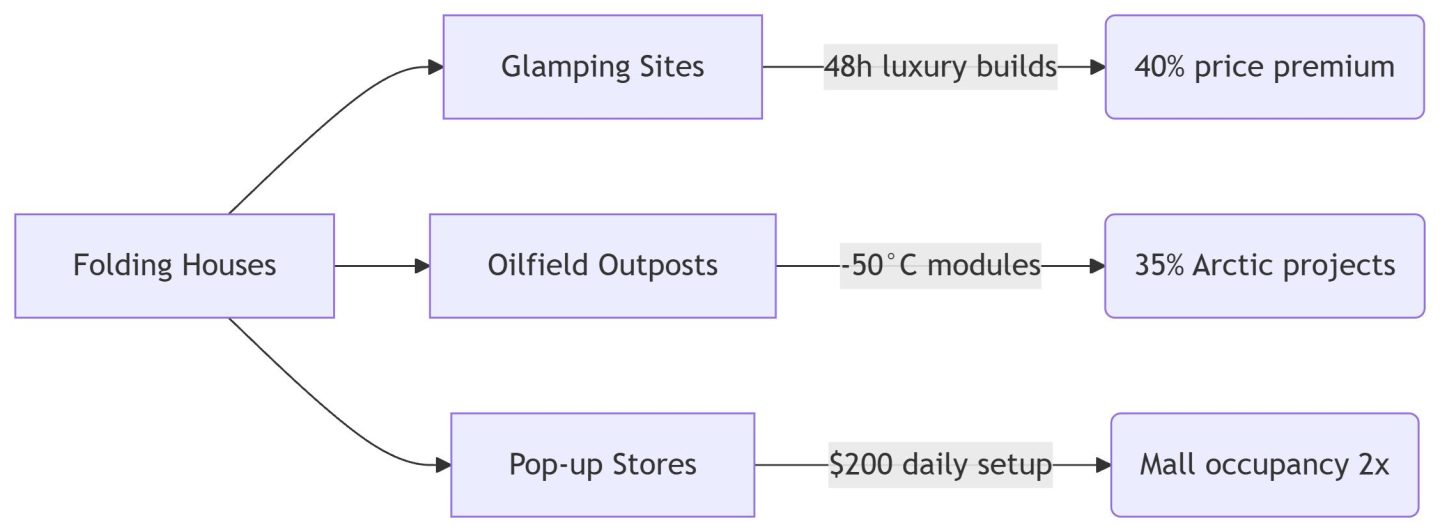

Commercial Applications

Cost Advantage Comparison

| Metric | Standard | Folding | Reduction |

| Transpacific Shipping | $18,000 | $5,400 | 70%↓ |

| On-site Installation | $6,000 | $900 | 85%↓ |

| Land Use | 4 parking spots | 1.5 spots | 62.5%↓ |

Industry Insight

“When shipping a house costs less than a flagship smartphone, global housing allocation becomes as efficient as express logistics.”

— Boxable CEO

China’s CIMC achieves 200 units/day production, turning “instant architecture” into scalable infrastructure. With 30+ countries adopting folding tech for public housing, the unfolding revolution is redefining how humanity shelters – proving that tomorrow’s cities may rise not from construction cranes, but from unfolding ingenuity.